-

Pipeline Pigging Systems

-

Pigging Cleaning System

-

Automated Pigging System

-

Drum Decanting Unit

-

DCS Distributed Control System

-

Automatic Batch Blending

-

Pigging Manifold

-

Rotary Lobe Pump

-

Internal Gear Pump

-

Pigging Valve

-

Sleeved Plug Valve

-

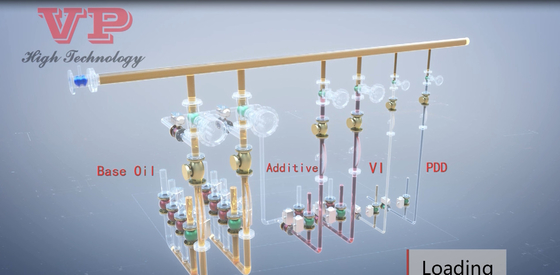

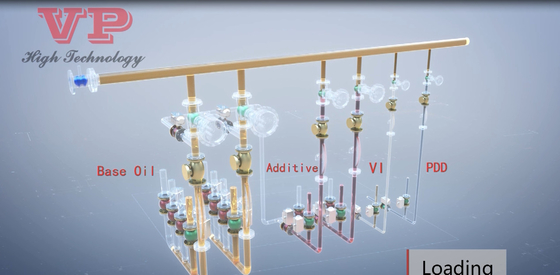

Simultaneous Metering Blending

-

Viscosity Improver Dissolving System

Environmental Friendly Lube Blending Lubricant Blender High Throughput

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Simultaneous Metering Blender | Place Of Origin | Beijing, China |

|---|---|---|---|

| Brand Name | Beijing VP Co., Ltd. | Application | Lubricant Blending/Specialty Chemical Blending |

| Function | Blending And Transferring | Packaging & Delivery | Seaworthy Packing With Wooden Case Or Pallet Or According To The Customer Request |

| Highlight | Environmental Friendly Lube Blending,Environmental Friendly lubricant blender,Lubricant Blender High Throughput |

||

Environmental Friendly - Cost Effective- Simultaneous Meterer Blender - BJVP

Overview:

The SMB is an extremly efficientlube oil blendingsystem providing very fast dosing of raw materials, together with high quality finished product results. All raw material components (base oils & additives) are pumped to the SMB from dedicated tanks, where a series of metering Channels equipped with mass flow meter, control valve and non-return valve allow very accurate and simultaneous dosing of all blend recipe components. The SMB design incorporates a fully piggable distribution header pipe in order to avoid cross-contamination between blend recipes and to maximise product recovery. This unique piggable SMB concept even allows for the different family groups of lubricating oils to be blended in the saure SMB and hence maximises plant equipment utilisation.

Applications:

- Lubricant Blending

- Specialty Chemical Blending

- Food and Beverage

- Daily- used Chemical

- Flavor and Fragrance

Advantages:

- High throughput capability

- Low internal contamination

- Reduce dosing modules

- Reduce investment

- Simply control