-

Pipeline Pigging Systems

-

Pigging Cleaning System

-

Automated Pigging System

-

Drum Decanting Unit

-

DCS Distributed Control System

-

Automatic Batch Blending

-

Pigging Manifold

-

Rotary Lobe Pump

-

Internal Gear Pump

-

Pigging Valve

-

Sleeved Plug Valve

-

Simultaneous Metering Blending

-

Viscosity Improver Dissolving System

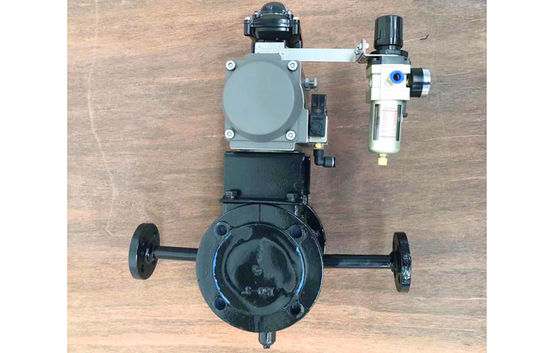

Customized ANSI150 Piggable Valves For Hygienic Pigging Process

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Pigging Valve | Place Of Origin | Beijing, China |

|---|---|---|---|

| Brand Name | Beijing VP Co.,Ltd | Application | Pigging Process |

| Temperature | -52~380 ℃ | Viscosity | 0.1~440,000 Cst |

| Highlight | ANSI150 Pigging Valves,ANSI150 Piggable Valves,ANSI150 Piggable Valve |

||

Pigging Valve - BJVP - Valve Technology - For Pigging Process

Overview:

BJVP pigging valves have been designed according to hygienic design guidelines to meet the high demands of process engineering applications. They build upon the same design principle as free flow arc valves. By virtue of this principle no products remain in the valves during operation. The prime use of BJVP pigging valves is with sterile pigging systems as they can be disassembled easily and quickly even when welded in place, and additionally, offer high CIP capability.

Parameters:

| Port size | 1.5”-12” |

| Pressure Standard | ANSI 150# |

| Temperature | -52~380℃ |

| Viscosity | 0.1~440,000 cst |

| Material | WCB,CF8,CF8M,Alloy |

| Port Type | ASME B16.5 RF* |

Features:

- Over-sized entry bore to accept swollen pigs

- Entry cap vent holes to provide positive release of trapped pressure before removal.

- Bleed valve connections (1/2" NPT) to facilitate a choice between venting and draining

- Integral Flanges

- Easy shop/field maintenance.

- Replacement parts and seal kits are readily available

- Positive stop plate is easily repositioned 90 degrees on the operating stem to accommodate flow direction.

- Operating stem is easily marked to verify the position of the ball

- Cap lugs ensure that pigs are fully inserted into the ball cavity eliminating binding when rotating the valve *- other standard available upon request.

Advantages:

There are several advantages of pigging valves over conventionally fabricated barrel-style launchers and receivers. The footprint required to accommodate a pigging valve is considerably less than the barrel-style launcher. Simplistic in operation as you are now operating a single quarter-turn ball valve instead of numerous valves that are associated with the barrel style.

Safety is enhanced by the inherent features and built-in redundancy as well as the reduced number of steps to perform the pigging operation. You also won't be in the line of fire for a projectile situation with the pig. The pigging valve is environmentally friendly if you are venting to atmosphere as the volume of media can be reduced by up to 91 percent.

Maintenance is simplified with a substantial reduction in the number of valves and the overall size of the configuration. The Argus pigging valve is widely accepted by junior, intermediate, and major oil and gas producers around the world.

Pictures:

![]()